Isoclima

15/09/2022

Share this post

In 2022, the group reaffirms its leadership in the bulletproof glass sector

“2022 is proving to be a year of resurgence for Isoclima, following the difficult period we all faced in the previous two years. But at the same time, it is a year of consolidation and marks a crucial step toward a five-year period of growth in markets and niches that align with the company,” says Daniele Santi, Commercial Director of Isoclima, thus emphasizing the Group’s leadership in the production of high-quality glass and transparent surfaces, highly technological products that stem from an engineering process undertaken in collaboration with the customer. “We are experiencing exponential growth in the nautical sector, which is driving us to organize strategic activities for adapting our organization and plants,” Santi explains. “More generally, I can confirm that our focus is increasingly on the future: we’ve been innovating since 1977, the year the company was founded, and we’ve never stopped embracing challenges.”

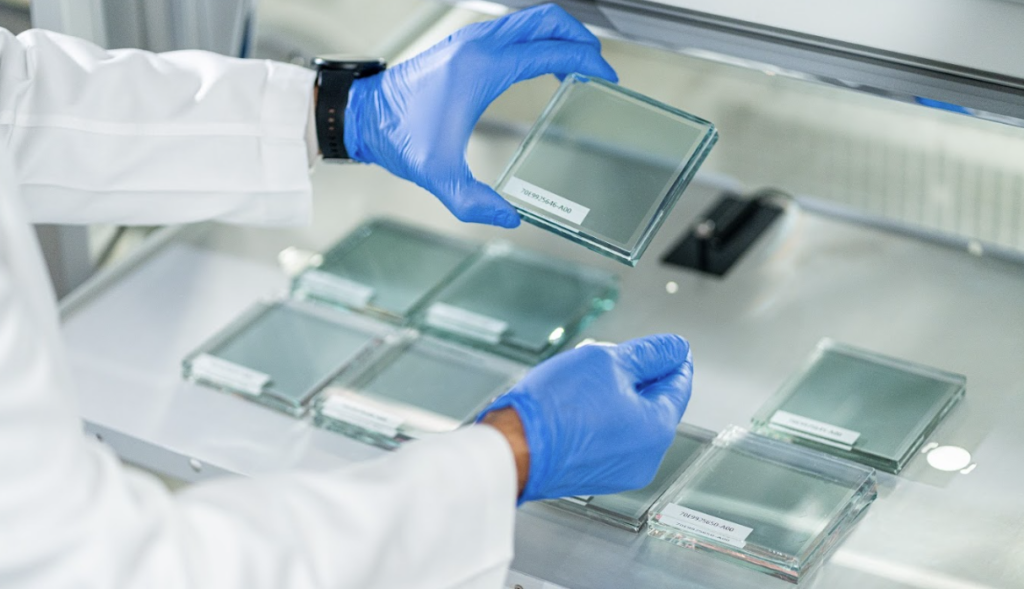

Today, Isoclima Group operates 7 production plants, holds 120 patents, employs 1,100 people (with 100 new hires in the first quarter of 2022), serves over 500 customers, and produces 500,000 square meters of glass. Specifically, the company provides transparent solutions for protection – in glass, polycarbonate, or acrylic – for applications ranging from armored vehicles to helicopters, luxury cars to yachts, rail transport to aerospace.

The company’s expansion began in the mid-1990s with the acquisition of other major glass industries in Mexico, and in the early 2000s, in Croatia. Since 2017, the entire multinational group has been part of the Stirling Square Capital Partners investment fund. In 2021, the company acquired the U.S. firms Dlubak Specialty Glazing Corporation (Pennsylvania) and Global Security Glazing (Alabama), which were merged under the single control of Isoclima Specialty Glass LLC.

But how is glass made resistant to impacts and mechanical stresses? “There are essentially two processes that allow this: chemical tempering and thermal tempering,” explains Santi. “Chemical tempering works differently from thermal tempering, although the final product is the same. At Isoclima, we decided to invest in chemical tempering because it is more aligned with our core business. On this front, 2022 represents an important turning point for us. We installed, at our Este plant, a facility capable of processing sheets up to 10 meters long. It is undoubtedly the largest plant in Europe, if not worldwide. And the results were immediate: the laminated spherical glass destined for the naval sector is a high-engineering and aesthetic product with unique characteristics, such as multi-radius 3D curvature, perfectly aligned and precise dimensions and geometries, ensuring a final performance that unmistakably bears our signature.”

But that’s not all. “Sustainability is also part of our strategic development plan, and its annual performance is communicated through the ESG Report. There are numerous ongoing projects and initiatives guiding us on a virtuous path of designing sustainable products, both by responding to market demands and by supporting customers in pushing in this direction, along with fostering a virtuous internal behavior,” concludes Santi.