Our long-standing collaboration with global giants in the rail and tram industry, based on trust and expertise, has led to the development of reliable products that we have been offering for years. Thanks to our experience, our customers find in our durable, high-quality glass the essential solutions for the safety and reliability of their trains. This trust is the foundation of our partnership and guides us daily to exceed their expectations.

Meeting Needs by Continuously Raising Quality Standards

In our laboratories, we strictly adhere to the technical standards required in the railway sector, from EN15152 regulations to ECE R43, ensuring that every glass we produce meets the most stringent safety and performance requirements. From impact resistance to shatterproof glass, we offer a wide range of solutions to meet every customer request, from locomotives and trams to high-speed trains. Our commitment to quality and excellence is reflected in our daily work. It is precisely the strict and meticulous regulations of the sector that ensure both ourselves and our customers that the work we do meets the standards set and the expectations of a company like ours.

Product Range

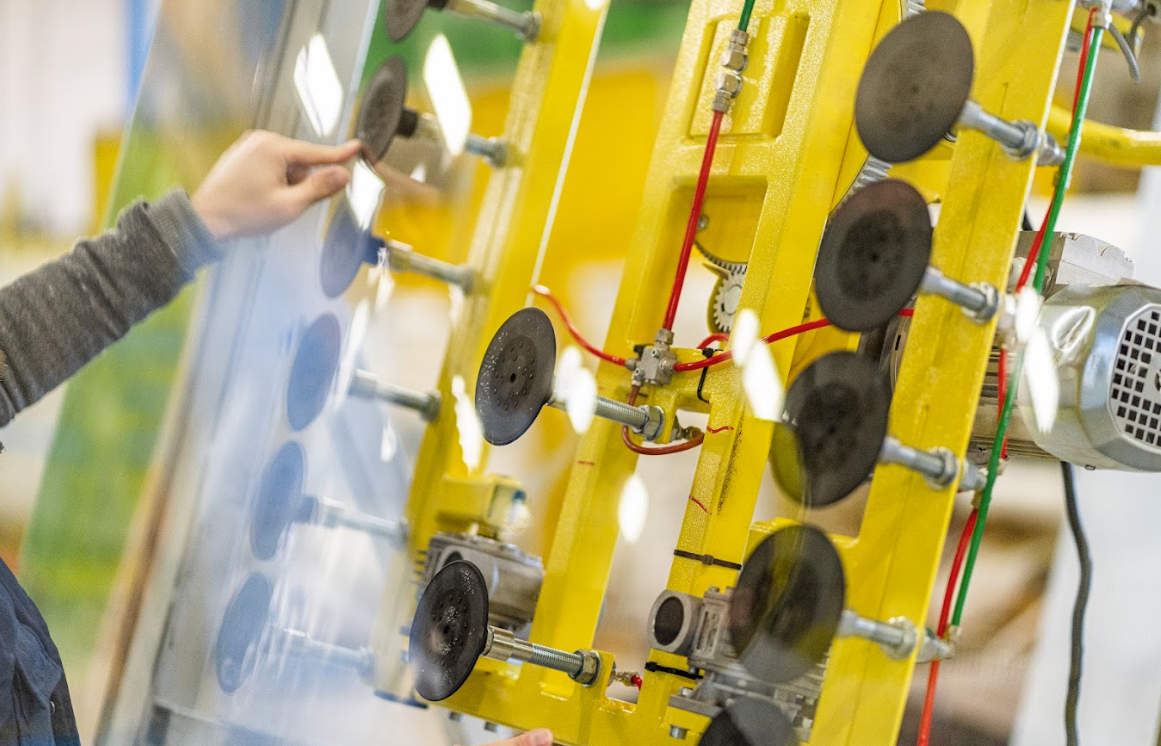

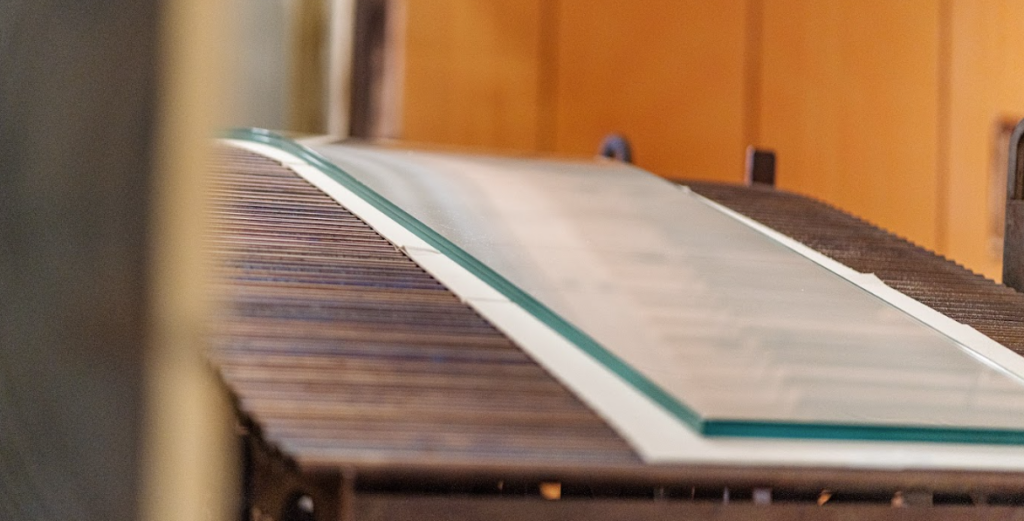

Isoclima offers a wide range of glass solutions for the railway sector, including windshields and side windows designed to ensure safety, comfort, and superior performance. Our windshields can be made in various shapes, including flat, cylindrical, or spherical, and are paired with an integrated heating system, which may consist of special coatings or micro-wires. Additionally, our glass is thermally or chemically tempered to ensure greater impact resistance and durability in extreme environmental conditions. The extruded or injection-molded seals ensure a watertight fit, while the lightweight alloy frame provides a robust and durable structure. The side windows for passengers, available in various shapes and sizes, are also equipped with cutting-edge technologies, such as lightweight aluminum alloy frames, infrared protection filters, and integrated displays. An example of this is the EN15152-certified windshield, designed to withstand speeds up to 580 km/h: it is equipped with an integrated heating system, aeronautical probes for precise temperature regulation, and an aluminum frame utilizing the innovative “ISOCLIMA DRY FITTING SYSTEM.” This system allows windshield replacement in just 20 minutes without adhesives or sealants, ensuring quick and secure assembly. Furthermore, the windshield is equipped with an internal anti-shatter film, which, in the event of an impact with an external object, prevents the projection of shards inside the cabin, ensuring added protection and long-lasting durability.

Design and Certified Products

Isoclima is the leading name in transparent glass for the railway sector, thanks to our ability to design and manufacture windshields, side windows, interior glass, and more for both traditional railway vehicles and for metro and tram systems. Isoclima product certifications comply with EN 15152 and NF F 15-818 standards, ensuring our customers the highest level of safety and regulatory compliance for every glass we deliver. Our clients can rest assured that they will receive products compliant with the most rigorous industry standards. We are proud to be the preferred partner for companies looking for cutting-edge glass solutions for their railway projects. An example? The Eurotram windshield in Strasbourg, currently the largest double-curvature railway windshield in service, or the NAT windshield, which is currently the only railway windshield certified for fire and smoke (AFNOR NF F 16-101) in all of its components, from the lightweight alloy frame’s painting process to the electrical junction boxes, from the injection-molded sealing gasket to the internal anti-shatter film.