Anticipating and promoting future trends with products and services.

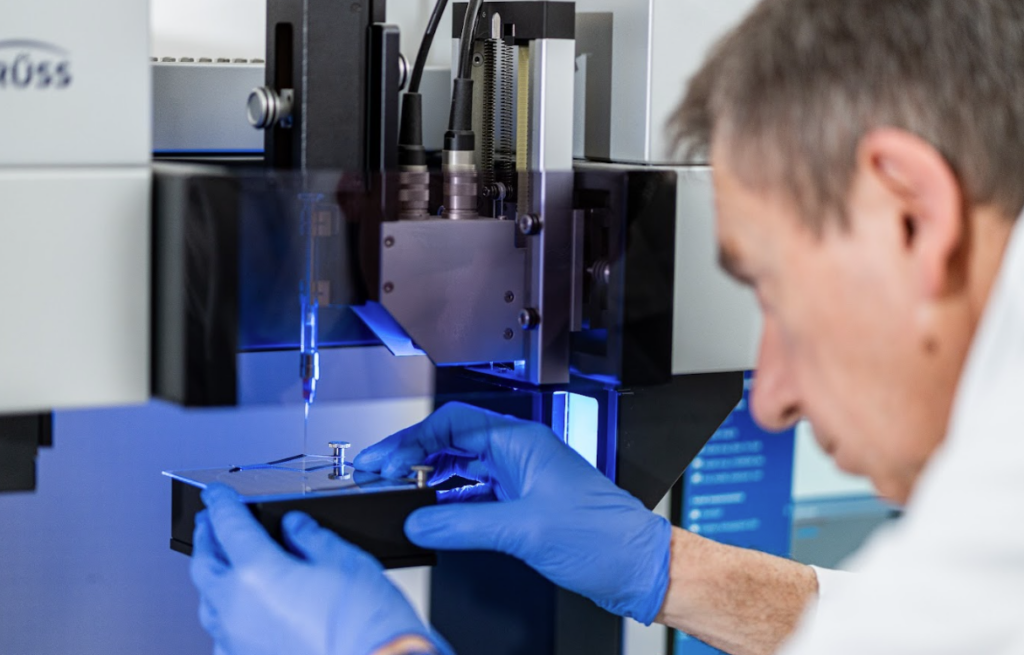

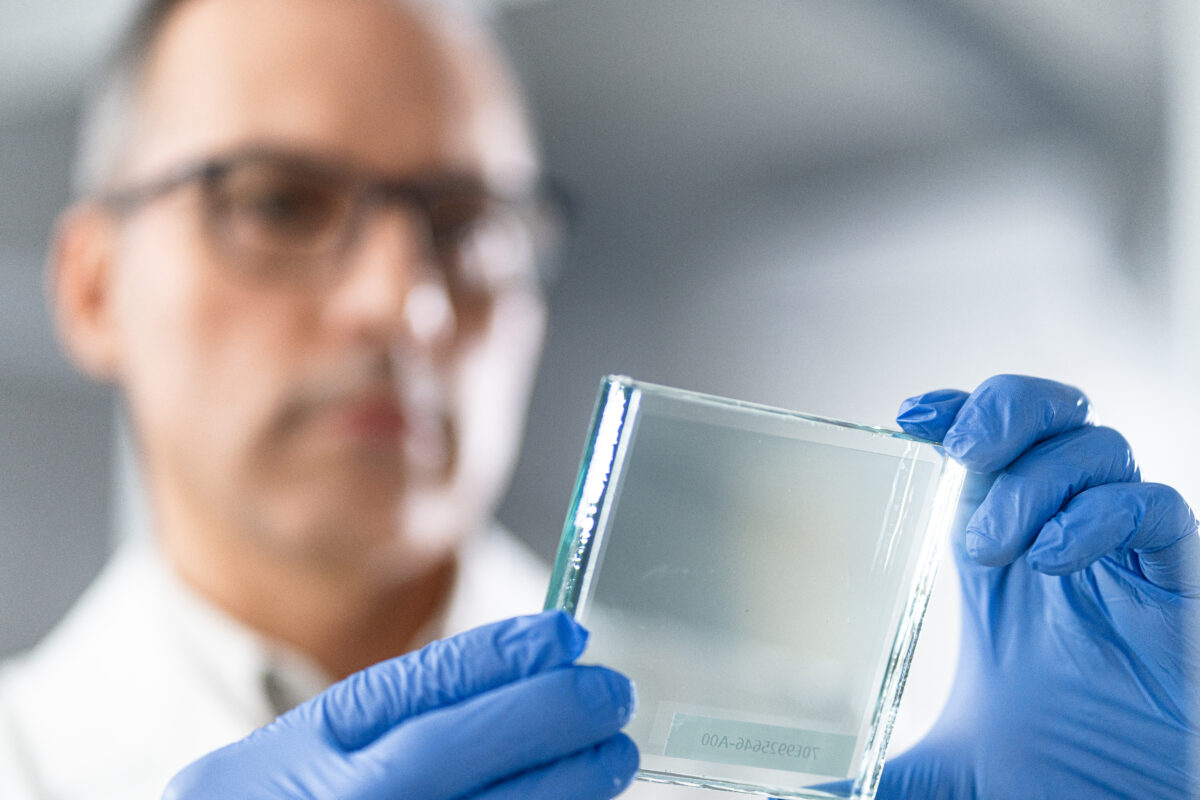

“More than just a supplier, Isoclima identifies itself as a partner that co-designs solutions, responding to needs that are sometimes very complex and technologically challenging. Innovation plays a pivotal role in our DNA, which is why we are often able to anticipate the trends of multiple sectors, without being affected by the cyclical crises we face, handling them with organizational flexibility and a now-consolidated compensation system. With a broad market outlook, we benefit from a constant business movement, always projected towards the future.” Daniele Santi, Commercial Director of Isoclima, emphasizes the Group’s leadership in the creation of high-quality glass and transparent surfaces, high-tech products that stem from an engineering process undertaken together with the client. “We provide a complete, highly customized package,” he points out, “where the competitive advantage we hold is shared with the client, regardless of the market they belong to. Recently, for example, we are experiencing exponential growth in the nautical sector, which has orders for the next three years, for which we are organizing strategic activities to adjust the organization and plants. More generally, I can confirm that our focus is increasingly future-oriented: we’ve been innovating since 1977, and we’ve never stopped embracing challenges. The recent pandemic, in a sense, froze the old world, marking a before and after, and we are already in that after. Urban transport, electric cars, hybrid boats, but even further ahead, we’re talking about autonomous driving, with vehicles that allow passengers to look around, and they will do so through ever-larger, smarter, and interactive windows, and drones designed for transporting people within the new metropolises. Throughout all of this, sustainability remains a priority, with investments in new 100% recyclable materials and 97% recovery of special waste.” Complex geometries, meeting specific requirements such as lightness, maximum safety, solar protection, acoustics, large sizes, and extreme curvatures with high performance (up to almost 10 meters, thanks to the bending furnace and the new chemical tempering plant, the largest in Europe, which will be inaugurated by the first quarter of 2022 in Saletto), are already a reality.

“Our solutions have become true case studies, and giants like Apple, Formula Indy, Leonardo, Mercedes, and the major shipyards –” adds Santi, “involve us in exciting and many futuristic projects. And we’re here: when something starts moving, we’re already ready.” Isoclima Group, with 5 production plants, 120 patents, 1,000 employees, over 500 clients, and 500,000 square meters of glass produced, excels also in post-sale services, with maintenance, monitoring, and timely interventions; 5% of turnover is dedicated to Research & Development, the beating heart of the Group and a forge of solutions where a team of professionals, creating unique patents, is able to revolutionize the market. “We can’t stop now, just as we are facing a new world,” concludes Daniele Santi, “and our mission will continue to be that of enabling present and future generations to see through.”